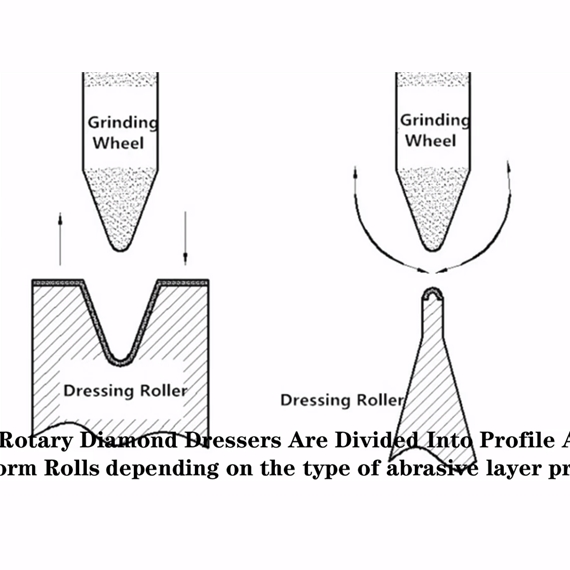

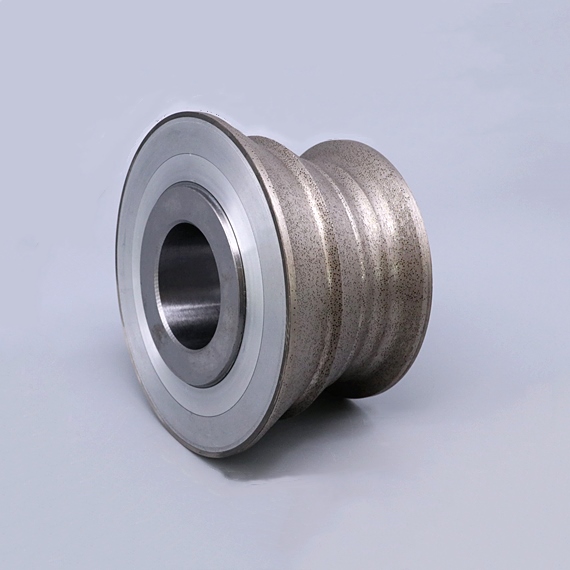

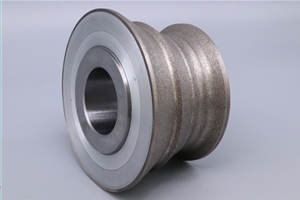

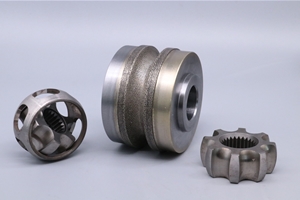

Profile rotary diamond dressers are used to form grinding wheels for many different kinds of mass production.

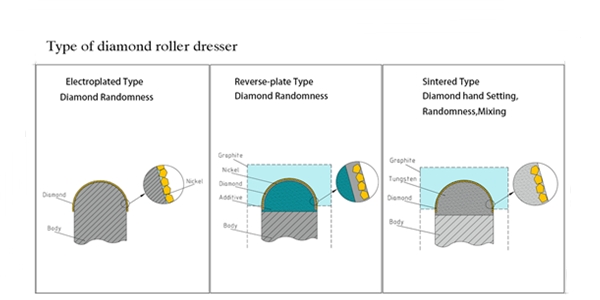

Profile rolls transfer a defined shape to the grinding wheel rim, which is used to generate the workpiece profile. Usually the profile of the roll corresponds precisely to that of the workpiece but it can also be adapted to the specific grinding. Shorter dressing time and long tool life leads to high productivity and consistent process conditions. Many kinds of conventional grinding wheels, and in special cases super-hard grinding wheels, can be dressed with this dressing method.

Dressing with rotating diamond tools has been found to be a reliable technique in series and performance grinding processes, especially those applications using vitrified bonded grinding wheels.

More diamond dressing rolls are used successfully in the following applications:

• the manufacture of ball and roller bearings,for grinding raceway profiles.

• drive technology for manufacturing linear guides, ball screws, gear teeth or racks.

• turbine industry for grinding the blades as well as the blade root and fir tree profiles.

• the automotive and -supply industry for grinding camshafts, crankshafts and gear shafts, fuel injection components, piston rings, joints, ball screw drives etc.

• grinding of precision tools such as taps, twist drills, milling cutters, reamers etc.

• general mechanical engineering for grinding hydraulic or pump components.